Advertisements

3D printing: how it's revolutionizing the industry It is no longer a futuristic promise or a concept reserved for innovation laboratories.

Today it is an active part of factories, hospitals, design studios and supply chains around the world.

This article rigorously and with a current focus analyzes how this technology is transforming production processes, business models, and strategic decisions in different sectors.

Summary

- What is 3D printing really and why does it matter?

- Direct impact on the manufacturing industry

- Key applications in strategic sectors

- Competitive advantages over traditional methods

- Current challenges and real limitations

- Near future and opportunities

- Conclusion

- Frequently Asked Questions

What is 3D printing and why did it change the game?

Talking about 3D printing involves referring to additive manufacturing, a process that creates objects layer by layer from a digital model.

Advertisements

Unlike traditional manufacturing, which often eliminates material, this method builds only what is necessary, with a precision that is hard to match.

The real change lies not only in the technique, but in the productive mindset.

Designing, testing, adjusting, and producing no longer requires months or large initial investments.

From an industrial perspective, 3D printing: how it's revolutionizing the industry This is explained by its ability to shorten cycles, reduce waste, and allow for previously unthinkable customization.

Real impact on the manufacturing industry

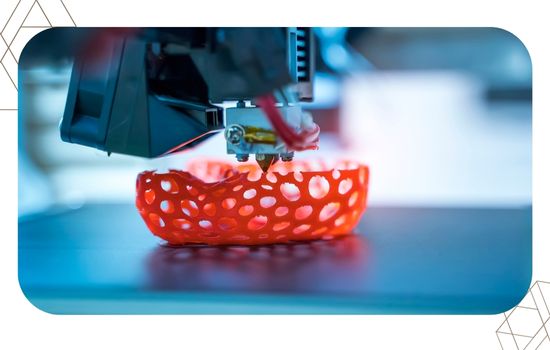

In modern factories, 3D printing is no longer an experimental resource.

Many companies use it for rapid prototyping, in-house tooling, and short-run production of finished parts.

A report from Wohlers Report 2024A recognized reference in the additive manufacturing sector confirms that more than 70% of industrial companies that adopted 3D printing reported a reduction in product development times.

This data reflects a concrete transformation, not a passing fad.

Manufacturing becomes more agile. Intermediaries are eliminated, parts are manufactured on demand, and dependence on large inventories is reduced.

Sectors where 3D printing is already making a difference

Automotive industry

Car manufacturers use 3D printing to create molds, functional parts, and custom components.

Saving time in design testing accelerates releases and improves operational efficiency.

Health sector

Hospitals and laboratories produce custom prostheses, implants, and anatomical models.

Here, 3D printing: how it's revolutionizing the industry It acquires a clear human value: solutions tailored to each patient, with greater precision and lower cost.

Aerospace

Aerospace companies are printing lightweight and strong components, optimized to reduce weight and fuel consumption.

The certification process is strict, but the progress is already an operational reality.

Construction and architecture

Although still expanding, 3D printing in construction allows for the manufacture of complex structures, reduces material waste, and accelerates projects in hard-to-reach areas.

Competitive advantages over traditional methods

Not all technologies change entire industries. 3D printing does, because it combines several advantages into a single process:

- Production on demand

- Significant waste reduction

- Design flexibility

- Customization without increasing costs

- Less dependence on long supply chains

As an analogy, 3D printing works like going from writing by hand to using a word processor: it doesn't eliminate creativity, but it multiplies speed, accuracy, and the possibilities for correction.

Practical example 1: internal industrial optimization

A medium-sized company in the metalworking sector in Latin America began to internally print spare parts for old machinery.

Previously, I relied on external providers with long waiting times.

After adopting industrial 3D printing, it reduced technical downtime and logistical costs, keeping operations running without relying on imports.

This type of application demonstrates how 3D printing: how it's revolutionizing the industry It also impacts businesses that do not produce technology, but do depend on operational efficiency.

Comparative table: traditional manufacturing vs 3D printing

| Aspect | Traditional manufacturing | 3D printing |

|---|---|---|

| Prototype time | Weeks or months | Days or hours |

| Material waste | High | Low |

| Personalization | Expensive | Viable |

| Production on demand | Limited | High |

| Initial investment | High | Scalable |

Read more: Renewable energy and technology: towards a greener future

Current challenges that should not be ignored

Although the discourse often focuses on benefits, it's important to maintain a critical perspective. 3D printing faces real challenges:

- High costs for specialized materials

- Speed limitations in mass production

- Need for trained personnel

- Strict regulations in sectors such as health and aviation

Ignoring these points creates unrealistic expectations.

The value of 3D printing: how it's revolutionizing the industry It's about understanding when to use it, not assuming that it replaces all existing methods.

Practical example 2: Personalization as a commercial advantage

An orthopedic device company incorporated 3D printing to customize splints according to the patient's anatomy.

In addition to improving clinical results, it managed to differentiate its brand in a highly competitive market.

Technology not only optimized processes; it also strengthened its value proposition.

3D printing and industrial sustainability

Another key point lies in the environmental impact. By manufacturing only what is needed, the waste of raw materials is reduced.

In addition, some industries already use recycled polymers and biodegradable materials in additive processes.

According to data published by the International Energy Agency (IEA)Optimizing production processes through advanced technologies can reduce energy consumption by up to 20 % in certain industries when applied strategically.

3D printing is part of that set of solutions.

The near future: what comes next?

Evolution doesn't stop. Advances in metal 3D printing, bioprinting, and hybrid manufacturing are expanding the industrial reach.

By 2025, the trend is to integrate 3D printing with artificial intelligence and advanced automation.

The key question is not whether 3D printing will continue to grow, but how each industry will decide to incorporate it intelligently.

Is your sector ready to adapt to a more flexible and decentralized model?

Conclusion

3D printing: how it's revolutionizing the industry It is not understood from empty enthusiasm, but from measurable results and concrete applications.

This technology redefines production times, costs, and possibilities, without promising magic solutions.

Those who analyze with sound judgment, invest strategically, and train teams gain real advantages.

3D printing does not replace the entire industry, but it does profoundly transform the way we create, produce, and compete.

Read more: Most promising innovations in solar and wind energy

Frequently asked questions about 3D printing in the industry

Will 3D printing replace traditional manufacturing?

Not entirely. It works best as a strategic complement, especially in prototypes, custom parts, and short production runs.

Which industries are currently benefiting the most?

Healthcare, automotive, aerospace, and advanced manufacturing are leading industrial adoption.

Is it profitable for medium-sized companies?

Yes, when applied to specific problems such as spare parts, prototyping, or customization.

Is the quality comparable to traditional methods?

In many cases, quality meets or exceeds standards, provided that appropriate materials and equipment are used.

If you're looking to understand clearly why 3D printing: how it's revolutionizing the industry It became a key issue in 2025; the answer lies in its tangible impact, its growing adoption, and its ability to adapt to real market needs.